Hey All! Back from the beyond! That being a waaaaay too long stay at the upholstery shop and a home remodel in the in between time. Finally have everything wrapped up on the house and now we can get back to tending to OCD (old car disease).

To catch up on the progress. Thrashed to get the car roadworthy and off to get our slot at the upholstery shop. Well... that went really slow, several months. Since I was tied up with the home projects I wasn't putting too much pressure on them to finish up, mistake! Once things got closer I started bugging him regularly and they finally got it done.

Then things took a turn from annoying to disheartening. Left his shop and got a few blocks away when things took the turn for the worst. Driving long at about 40mph the right front wheel locked up solid in an instant. Managed to keep her out of the ditch and got to a safe stop. Had to have her hauled home (50+ miles).

At the time I was still in the remodel mode and truthfully pretty pissed off at the whole thing and needed to step back.

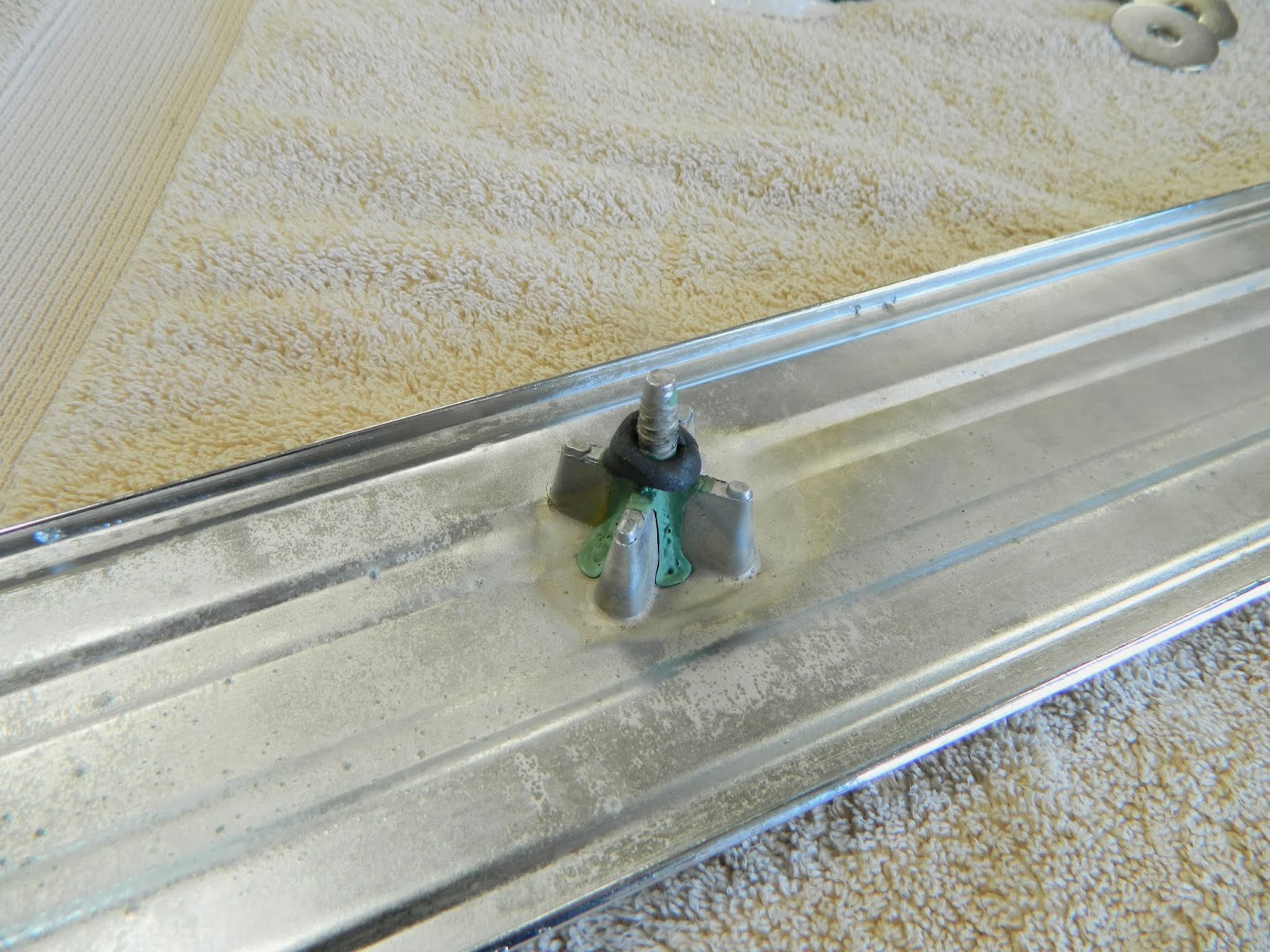

A few weeks back I did a tear down of the right front to figure out what happened and what parts I needed to fix it. Turned out that in my haste to get it to the upholstery shop I failed to torque the caliper abutment bolts. That is the bolt that holds the caliper mounting bracket to the upright (spindle assembly). So when the lower bolt came out the caliper hinged outward and locked itself into the wheel (catching a high spot on the weld that attaches the hoop to the center section of the wheel). So that means that the RF wheel went from 40+ mph to ZERO in a millisecond.... not cool at all! Parts damaged were: Caliper, Abutment bracket and the upright. Thankfully the wheel came out unscathed other than a burr where the caliper caught it. I was able to smooth that out.

It pisses me off the most that I got in a hurry and missed that bolt and then the car sat at the upholstery shop anyway.....Oh well, over it now. Won't be going back there. The interior came out nice and I am pretty happy with how it looks. Pics to come soon on the interior.

Still cleaning.... The car sat in their shop all that time. And the shop there was all one big room. That means all the woodworking stuff is in the same room. Tablesaw, routing table, various sanders etc. Soooooo, from top to bottom inside and out is covered in a thick coat of dust..... Just want to get past all of this and move on.

Re-checking EVERY bolt one the car for my own confidence that she will be safe and roadworthy. Lesson learned, never get in a hurry!!!